Our pottery workshop

Terracotta ceramics with variable porosity

Poterie JAMET has been designing, manufacturing and distributing terracotta ceramics for 3 generations and has been approved as a Historic Monument of France since 1979*.

6 collections of technical ceramics with variable porosity

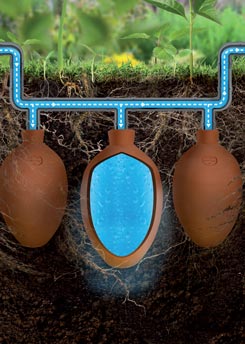

- IRRIGATION: Ollas Jamet ®, professional irrigation ceramics, 3 Collections available ( Ollas Jamet ORIGIN ®, SPELEO ® and Mini-Greenhouse ®)

- ENTOMOFAUNA: insect support ceramics, in particular pollinators: Ollas BEE® bee LOGE® insect

- VINIFICATION: Dolias Jamet®, ceramics for vinification, aging and refining of wines and alcohols (Sept 2022)

- RECYCLING: composting ceramics and vermicomposter (New in 2023)

- ORNAMENTATION Terres d’Iza ornamental ceramics guaranteed for life against frost, (2023)

- MATERIALS FOR FIREPLACES: historical craft of the factory, Miters and Lanterns for fireplaces approved as Historic Monuments.

5 reasons to choose Ollas Jamet

Since 2012, our professional irrigation ceramics have provided great comfort of use and well-being to plants, proven by the increase in biomass*

The greatest autonomy and irrigated surfaces

from 3 to 45 days for 0.13m² to 10m² thanks to optimized porosity.

The most efficient irrigation on the market*

Saving water and watering time, cheapest irrigated area on the market.

The greatest durability

3-year warranty** against frost, limescale, tree root pressure and soil acidity.

The widest range of ollas on the market

15 models to bury from 0.5 to 35 liters and 6 models to plant.

100% made in France

Manufacturing in Loudun (86) based on French land free of any pollutant.

* Tests carried out and measured by the independent ASTREDHOR technical center in a temperate oceanic climate.

** Against frost, limescale, tree root pressure and soil acidity.

Manufacturing process

Pottery JAMET controls all the development and manufacturing processes, from the choice of raw materials, all French , to firing.

We manufacture our own so-called “unwashed” molding paste in-house, give our ceramics long rest times before and after shaping, then we watch over the various firing phases and test the quality of each batch.

Our craftsmanship allows a production of superior quality called PROBUS Poterie JAMET , in accordance with the highest requirements required by professionals in beekeeping, naturalists, plants, winemaking and ornamentation.

Research and development

The creation of a new collection requires between 1 to 4 years of research and development .

The tests in real conditions, the methods and the results of Pottery JAMET ceramics are defined, carried out and confirmed by and for leading professionals in their respective fields:

- Exterior architects and landscape architects

- Local authority leaders

- Producers of market gardening, tree crops and truffles…

- Winegrowers, oenologists, cellar and winemaking masters

- beekeepers

- Manufacturers of containers / pots / greenhouses and other equipment for green spaces

In irrigation, the observation of all private or professional plant customers is unanimous, the OLLAS-JAMET provide great ease of use, water and time savings, plant well-being tested by our technical partner ASTREDH GOLD Pays de Loire .

They also have the highest surface irrigation efficiency and autonomy.

Production

Since 2018, Poterie JAMET has been investing in the production tool with the extension of a workshop and additional jobs to meet growing demand and also prepare our future collections and innovations.

Annual production capacity:

- 2018 -> 10,000 pieces

- 2019 -> 20,000 pieces

- 2020 -> 30,000 pieces

- 2021 -> 50,000 pieces

- 2022 –> 100,000 pieces

Bursting rate at the oven outlet: < 1% (including prototypes)

Manufacturing times

From mixing the raw earth to the end of firing, the manufacturing time varies from:

- 2 to 4 weeks for turned Ollas 4 to 8 weeks for Beekeeping Ollas > 100 L and ornamental ceramics

- 5 to 10 weeks for winemaking ceramics

Master ceramicists

The strength of a brand comes from the reality of its history, the truth of its products and the values they represent, but first of all from the know-how and the will of the men and women who make it up.

Pottery JAMET, these are 3 Master ceramists, guardians of ancestral know-how and resolutely turned towards innovation:

- Laurent JAMET , CAP pottery turner 1987 At CNIFOP 58 St Amand en Puisaye

- Isabelle JAMET , CAP Ceramic industrial fabricator 1983 High school of ceramics

- Nadine GENDRON , CAP pottery turner in 1986 At CNIFOP 58 St Amand en Puisaye

They carry out all the production and since 2020 have been training new turners and apprentices in the pottery profession.

Our history

Pottery JAMET, a story that begins in 1974 in the heart of France.

For 3 generations, the Jamet family has been in the world of ceramics.

1st ceramic

The largest amphora in France

Creation of the workshop in Loudin

Resumption of the workshop by Laurent Jamet

Ollas R&D

Marketing of Ollas

Professional Ollas

Lands of Iza

Ollas Jamet ORIGIN range

Large volume ornamental pottery

Winemaking R&D

1st winemaking tests

Ollas Jamet ORIGIN® large volume

Ollas Jamet SPELEO®

bee trough

Ollas Jamet MINI-GREENHOUSE®