Our expertise

Only the human hand, by controlling the pressure exerted on the dough to be shaped, can guarantee the ideal balance between resistance and porosity"

Laurent Jamet

1. Preparing the Jamet Pottery shaping dough

Each of the raw earths has specific properties of porosity, mechanical and thermal resistance, ease and resistance to shaping, essential for large parts.

They are first extracted from quarries, then left to weather for a long time. This allows the fermentation of organic matter which naturally improves the elasticity and the homogeneous mixture of the different clays.

They are then mixed, always dry, in precise proportions for each collection. Depending on the collections and sizes of the pieces to be manufactured, Poterie JAMET will carefully adjust the grain size of the "fine earths" and the proportions of the mixture of each of them.

This essential operation makes it possible to obtain ceramics with only the natural and homogeneous grain of "fine earths", without any other hard rock or chamotte.

The various JAMET Pottery “homemade” clays, with this graining, have a much more solid and homogeneous internal structure than “classic” clays with or without the addition of a “Chamotte”.

This unique process gives JAMET ceramics exceptional resistance and durability, making them insensitive to frost and allowing various degrees of porosity to be chosen according to the collections. Even when thick, Ollas-Jamet® provide excellent porosity for perfect irrigation, just enough, thanks to the precise "graining" developed by Poterie JAMET.

This is why we adjust each preparation with one or more of our crushed and sifted earths in order to obtain the perfect mixture guaranteeing the technical characteristics of porosity and resistance. For Ollas JAMET®, 3 different clays are used. Water absorption tests of the dry mix are then carried out to check the level of porosity and elasticity of the future dough to be shaped before wetting and mixing. If necessary, the dry mix is again adjusted with one or more earths reduced to fine dust until the correct mix is obtained.

We knead the wet and rested dough one last time, then put it in an extruder which extracts the air contained in the dough in order to manufacture compact clay blocks, calibrated according to the size of the pieces to be worked.

The shaping paste is now ready to use for rope assembly of large containers or the turning of Ollas-JAMET®.

2. Manufacturing

Lathe making

Lathe manufacturing concerns all standard size Ollas (<50/75L).

The potter takes his loaves calibrated on a lathe with the markings corresponding to the pieces to be produced.

The production of these collections on the wheel can only be manual "because only the human hand, by controlling the pressure exerted on the dough to be shaped, can guarantee the ideal balance between resistance and porosity" according to Laurent Jamet.

The Jamet family's experience and mastery of filming allows:

- A rapid production rate for small or medium volume parts.

- Regular production of large volume parts.

- Turning parts > 15 kg.

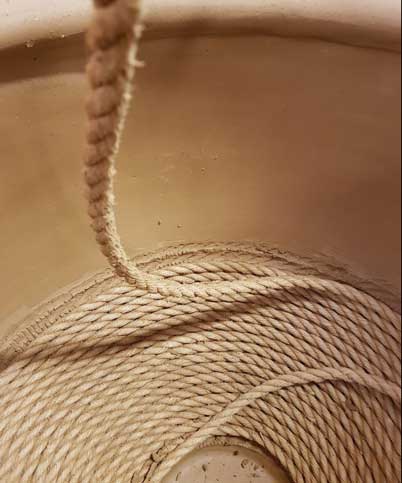

Rope production

Rope manufacturing only concerns custom-made Ol-BEE Jamet® > 100 L and 200 L intended for professional beekeepers for large transhumant colonies or not.

This ancestral knowledge has been taken up and perfected by Poterie Jamet since 2005.

- The potter first makes a wooden template reproducing the internal shape of the piece to be made.

- A hemp rope is then wrapped around the jig all the way up.

- Once the model is finished, its surface is smoothed or decorated, or even in some cases, engraved with the name of the beekeeping domain.

- After the clay has hardened, the wooden template is dismantled from the part and removed.

- The first turns of rope are removed to finish the collar. The rope can then also be removed but little by little, with a height of 5 cm to 20 cm per day depending on the weather conditions. She will leave her mark inside the room.

- The interior of the ceramics is smoothed or left raw with the traces of rope according to the customer's requests.

3. Drying

All collections are gently dried in our 3 ventilation rooms, mostly at room temperature.

Ventilation, temperature and humidity are constantly monitored and readjusted according to weather conditions, if necessary.

This allows the ceramics to dry gently, without rushing them, keeping the homogeneity of their internal structure intact.

This simple, but essential operation, requires the necessary time because it contributes to the mechanical resistance of the ceramics and prevents them from any micro-cracks which then reflect their capacity of radius of action and autonomy of irrigation.

Pottery JAMET's 45 years of experience have taught us never to force this crucial stage in the quality of Ollas-JAMET ® and decisive in avoiding cracked or non-cracked ceramics, but with micro-leaks, after firing.

Drying time

The natural drying of Ollas mounted on the wheel varies between 2 days and a week depending on their size and weight.

The drying of JAMET® Ceramics mounted by rope, including removal of the rope, will last between 3 and 5 weeks depending on the weather, the size and complexity of the pieces.

- Ollas-JAMET® Lathe ceramics drying from 2 to 7 days.

- Ollas-JAMET® Rope Ceramics drying from 2 to 7 days.

- JAMET® Ornamental Ceramics drying time of 3 to 5 weeks.

- JAMET Vinification Ceramics drying for 1 to 2 months.

4. Cooking

Once the Ollas have dried, they are methodically put in the oven, in order to have an even circulation of heat around each piece. We carry out a long cooking with different stages and cooking times, as well as an overcooking phase.

The firings are carried out in 2 ovens, one with a small to medium capacity and the other with a very large volume (a full semi-trailer).

Our cooking techniques and programming have been designed solely with the aim of optimizing and finalizing our entire manufacturing process to guarantee superior quality in line with the expectations of informed users.

Ollas-JAMET® ceramics:

- Tour mounted, cooked for 10/12 hours with overcooking at 1,100°C.

- Climbed with Ollas-JAMET® Rope, cooking for 14 hours with overcooking at 1,100°C.

Ornamental ceramics:

Firing for 14/16 hours with overfiring > 1,200°C.

Vinification ceramics:

Firing for 16/18 hours with overfiring at 1,200°C.

5. Quality control

A quality control specific to each collection is carried out on a few samples. This protocol, resulting from more than 45 years of experience, validates the quality of the whole batch.

The rate of loss of ceramics that do not comply with the “JAMET professional quality” charter from the start of shaping to the end of firing is less than 1% including the prototypes , which in pottery craftsmanship is exceptional.

6. Shipping

Pottery JAMET, ships its production throughout France and for export by land, sea and air freight according to the quantities and deadlines desired.

All orders, even for a single piece, are packed, palletized and wrapped in a stretch-blown-opaque film, which is very resistant and protective.